A team of bioengineers at the

University of California, Berkeley, has developed a new kind of environmentally

friendly adhesive polymer. In their study, published in the journal Science,

the group used an electrophilic stabilizer to prevent a certain fatty acid from

depolymerizing, thereby enabling its use as an adhesive.

Zhibin Guan, a chemist at the University of California, Irvine, has published a Perspective piece in the same journal issue outlining the work done by the team.

As Guan points out, polymer adhesives are used for a wide variety of applications. But, he notes, most are tailored for a specific use, joining wood for example, and cannot be used in different contexts. Making things worse, many adhesives are hazardous to plants and animals, creating an environmental problem.

The research team's goal was to develop a sustainably sourced polymer adhesive that could be used for a wide variety of medical and nonmedical applications.

The research team turned to polymers that are derived from α-lipoic acid (αLA), a naturally occurring fatty acid that breaks down naturally. They found that use of an electrophilic stabilizer could stop the polymers from breaking down, allowing for the creation of a whole family of adhesives, all of which were environmentally friendly because they could be easily broken down when desired. Each of the new adhesives they developed was tested across a range of applications.

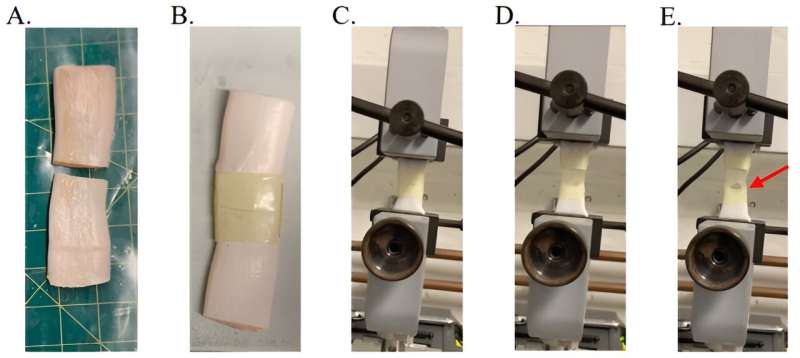

As part of their testing, they found that αLA-based adhesives could be used for wood, metal and tissue mending and that they would not harm the environment. They also found that one type of pressure-sensitive adhesive they developed had 10 times the peel strength of conventional products and that it worked in both wet and dry conditions.

The family of adhesives in general had approximately the same strength as adhesives derived from petroleum-based products. Also, many of them were self-healing, making them ideal for use in medical applications.

Taking their work a step further, the research team also developed what they describe as a closed-loop recycling process that allowed for making new adhesives out of old ones by adding an aqueous media.

Previous page

Previous page Back to top

Back to top