Graphene itself has some

incredibly useful properties, as an ultra-strong, ultra-thin and flexible

conductor of heat and electricity. By making alterations to the underlying

structure of this wonder material, scientists at the University of Sussex have

extended its capabilities even further to create the tiniest microchips yet.

As a two-dimensional sheets of carbon with a thickness of a single atom, graphene is an incredibly versatile material with great potential in many areas. We’ve seen how these sheets could be wrinkled to become advanced water filters, scrunched up to become ultra-sensitive cancer sensors or crumpled up into balls for next-generation battery parts.

The University of Sussex team was experimenting with the ways that physically deforming these two-dimensional sheets can alter their electronic and mechanical properties. This technique is called “straintronics” and usually involves conventional electronics, but the team's approach centers on the idea of using nanomaterials as a way of freeing up space inside devices to make room for more chips.

“Using these nanomaterials will make our computer chips smaller and faster,” says study author Alan Dalton. “It is absolutely critical that this happens as computer manufacturers are now at the limit of what they can do with traditional semiconducting technology. Ultimately, this will make our computers and phones thousands of times faster in the future.”

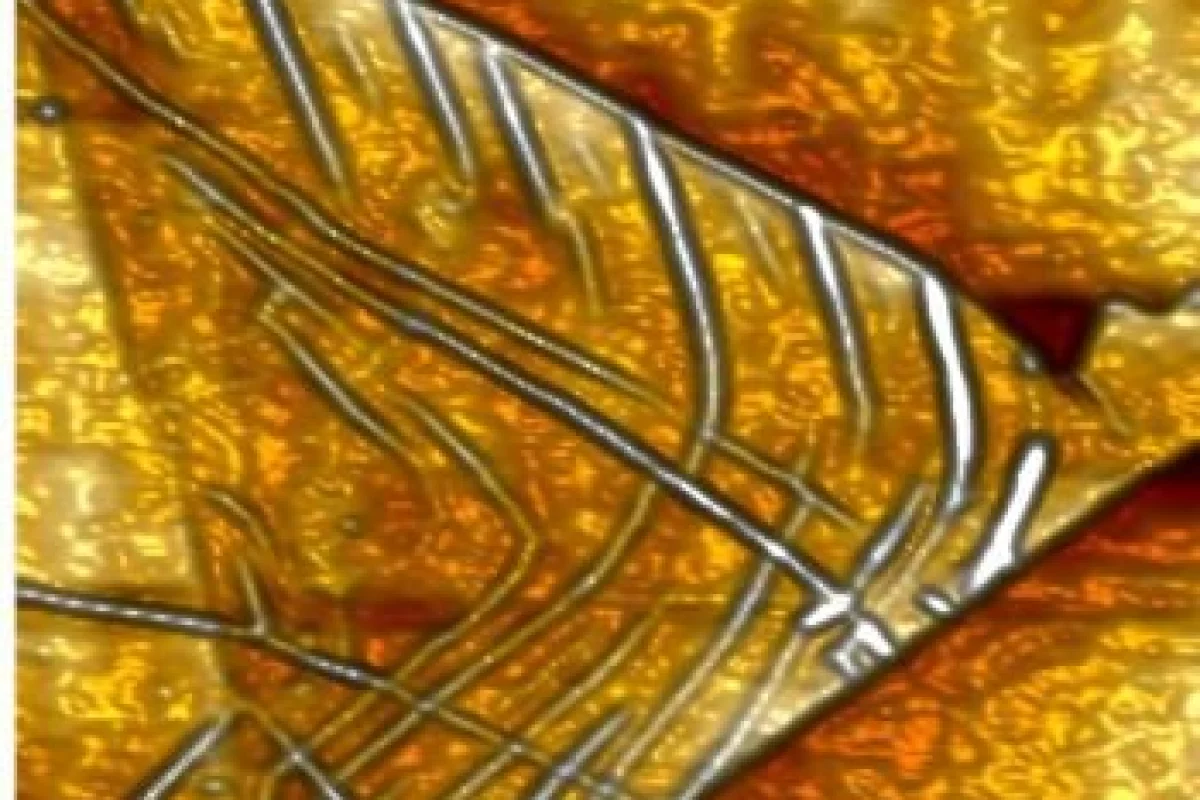

The team’s experiments involved adding collapsed and folded wrinkles and other alterations in a process likened to “nano-origami,” with the team finding that adding structural kinks to strips of graphene caused them to behave like transistors and in turn tiny microchips. So tiny that the device is said to be around 100 times smaller than a conventional microchip.

“Instead of having to add foreign materials into a device, we’ve shown we can create structures from graphene and other 2D materials simply by adding deliberate kinks into the structure,” says lead author Dr Manoj Tripathi. “By making this sort of corrugation we can create a smart electronic component, like a transistor, or a logic gate."

In addition to not requiring any extra materials, the researchers say such processes are greener and more sustainable than current chip manufacturing techniques as they can be performed at room temperature, meaning less energy is required.

The research was published in the journal ACS Nano.

Previous page

Previous page Back to top

Back to top