The next generation of scientists

and inventors is already finding approaches to address society's problems.

Today, a group of high school students and their instructor report a solution

to the problem of lead contamination in drinking water—an inexpensive faucet

attachment that removes this toxic metal. Unlike conventional filters currently

on the market, theirs includes a cartridge made with biodegradable plastic and

indicates when it's "used up" by turning the tap water yellow.

The researchers will present their results today at the spring meeting of the American Chemical Society (ACS).

"A few years ago, I saw a video of a woman in Michigan turn on her tap water, and it came out brown," says Rebecca Bushway, who is the project's principal investigator. She's also presenting the work at the meeting. "That made me think—because there's really no safe level of lead in drinking water, wouldn't it be nice to have a water filter that could tell you that your water is contaminated, well before it turns brown because of lead?"

Although some pipes have been remediated in the U.S., millions of homes, especially those in low-income communities, still receive drinking water through lead-containing pipes. If the water's chemistry isn't ideal, or it flows quickly because of high demand, then pipes can corrode. When the corroding material contains lead, the toxic metal dissolves or flakes off into the water, contaminating it with a dark discoloration and sometimes visible particles.

Until old pipes can be replaced with lead-free versions, filters can help remove or reduce this pollutant from tap water. Although various lead filtration systems exist, their high cost and large size can be barriers. In addition, few of them provide any indication that they should be changed, and none indicate that the water could pose an immediate health risk.

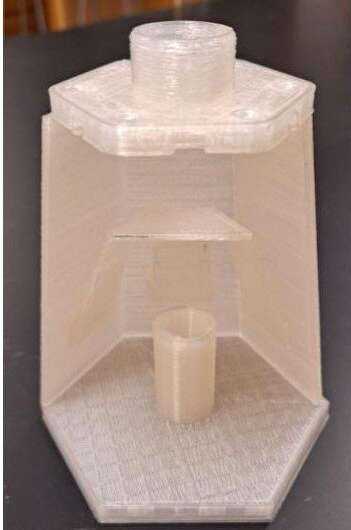

Bushway, a science teacher at Barrie Middle and Upper School, wondered aloud to her upper-level high school chemistry class if there was a little filter—similar to the ones that are made for camping to purify water—that they could make from inexpensive components to easily remove lead. The students were excited about the idea, and they started thinking about the project in 2020 when COVID-19 restrictions kept them out of the classroom. While at home, the team met virtually and discussed designs for an attachment to screw a filter onto a sink's faucet. Then in the spring semester of 2021, when they returned to the classroom, they 3D printed the attachment and a 3-inch-tall filter housing, using a biodegradable plastic. Their final step was to fill the cartridges with a mixture of calcium phosphate and potassium iodide powder.

"Calcium phosphate first binds with dissolved lead in water to form lead phosphate and free calcium. The calcium, which is harmless, ends up in the water, and the lead phosphate stays in the filter," explains Bushway. Lead phosphate, which is an inert solid, is trapped inside the filter by a nylon screen on the bottom of the unit. Once the reaction capacity of the calcium phosphate is reached, dissolved lead reacts with potassium iodide, which turns the water yellow, an indicator that lead is present.

And while the chemistry itself is pretty straightforward, crafting the water filtration system to do what the researchers intended has been more complicated. For instance, calcium phosphate tends to clump up, causing the reaction rate between it and lead to go down as the surface area decreases. So, the team's lead student engineer incorporated hexagonal bevels inside the filter. "That's an innovation, which came from one of the high school students, that will make the water spiral as it goes through and keep the powder from clumping," says Bushway.

Next, the students will add a tiny spectrophotometer with a single-wavelength LED to the bottom of the filter cartridge, where the water gets dispensed. Their plan is to have an indicator light that turns on as soon as the detector identifies the yellow color of the lead iodide. Bushway says this will indicate that lead is in the water, even before the color is detectable by a human eye.

The team's goal is to make and sell their filters for less than $1 each, which Bushway thinks they're on their way to doing. Because the housings use biodegradable plastic, the cost could trend a little higher, but the material would help reduce the overall environmental impact of the filter.

The process of developing the filter has been very fulfilling, according to Bushway. "Ultimately, this experience has shown students that they can make a difference to somebody, and there are problems that they can fix with science," she says.

Previous page

Previous page Back to top

Back to top