When we're hot and sweaty, we

prefer cool mesh-like clothing, but otherwise … mesh just doesn't keep us warm

enough. A new dual-purpose fabric was designed with that conundrum in mind, as

it features cooling vents that open upon absorbing sweat.

The material is being developed by a team of scientists at North Carolina's Duke University, led by Asst. Prof. Po-Chun Hsu. It's essentially just nylon which is coated on one side with a thin layer of silver, and that has rows of tiny flaps cut into it.

When the inward-facing, non-silver-coated surface of the nylon absorbs water – such as that which is found in sweat – it swells up. This phenomenon causes each flap to curl outwards, toward the side on which it's attached. When the material later dries out, the nylon shrinks back to its original volume, closing the flap.

The 50-nanometer-thick layer of silver was added to reflect body heat back in toward the wearer, helping to keep them warm when the flaps are closed.

Initially, Hsu wondered if the added weight of the metal would hamper the curling effect. As it turns out, though, the silver actually boosts the curl. This is due to the fact that because the silver on the top surface of each flap doesn't swell, the underlying nylon is forced to expand more on the bottom than on the top, causing it to curl even more toward the top (and to one side).

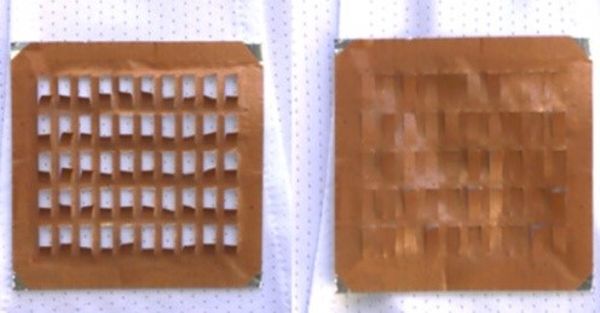

Instead of having entire garments made out out of the material, the team envisions patches of it being strategically placed in areas where people tend to sweat more. In order to test its cooling effect, the scientists made a square 6-by-6-cm (2.4 by 2.4-in) patch with flaps that were each a few millimeters long.

It was found that as compared to a solid patch made of a traditional polyester/spandex blend, the vented patch was 16 percent warmer when the vents were closed, and 14 percent cooler when added moisture caused them to open.

Hsu and colleagues are now looking into ways of making the flaps even smaller without any loss in functionality, plus they're hoping to replace the silver with a nanocomposite that could be made in any color.

A paper on the research was recently published in the journal Science Advances.

Previous page

Previous page Back to top

Back to top