Water electrolysis is an

effective method for producing hydrogen using renewable sources of energy. The

development of cost-effective electrocatalysts for efficient and durable

hydrogen evolution reaction in alkaline media is of vital importance to meet the

increasing demand of hydrogen.

The platinum group metals exhibit excellent activity in hydrogen evolution reaction, but their high cost hinders their widespread application.

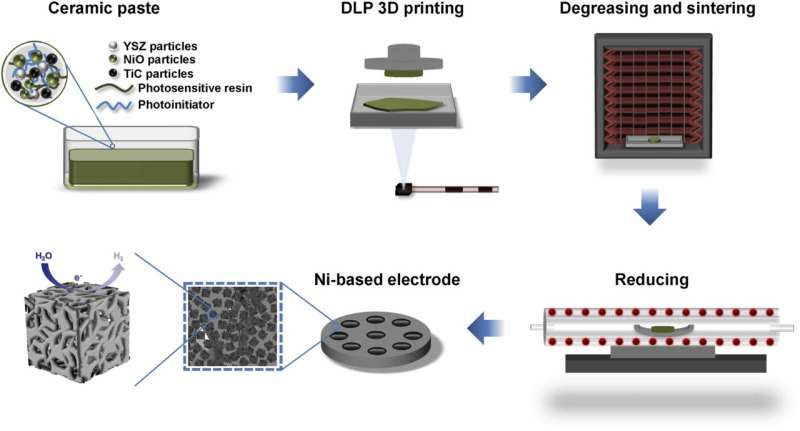

Recently, a research team led by Prof. Tang Zhiyong and Associate Professor Zhang Jie from the Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences has proposed a novel photo-curing 3D-printing method to directly manufacture structured nickel-based electrocatalysts with unique gluten-like cubic structure and strong catalyst-substrate interaction.

The study was published in Nano Energy.

The photo-curing 3D printing has a much lower manufacturing cost than that of the selective laser melting 3D printing, and much higher degree of freedom and printing accuracy than that of direct ink writing 3D printing.

Based on this technology, the researchers optimized printing paste composition and post-treatment process. The resultant electrode surface exhibits gluten-like cubic structure, where Ti exists in amorphous state with strong interaction with Ni, leading to increased active sites and improved electrolytic properties.

The tailored nickel-based electrode exhibits excellent durability and a remarkable low overpotential, surpassing the commercial Pt/C catalyst and most of the state-of-the-art electrocatalysts.

Density functional theory calculations further reveal that the Ti doping decreases water dissociation energy barrier and hydrogen energy barrier, thus enhancing the hydrogen evolution reaction.

This work provides a novel strategy to precisely prepare the structured noble-metal-free catalysts with enhanced activity in alkaline water electrolysis. Moreover, the developed photo-curable 3D printing method provides an alternative option for manufacturing low-cost electrocatalysts with complex 3D architecture.

Previous page

Previous page Back to top

Back to top