Ensuring manufactured goods and

components have not been copied and replaced illegally by counterfeited goods

is a high-priority concern of the manufacturing and defense industries in the

U.S. and around the world.

A potential solution would hold wide-reaching impacts and implications in various areas ranging from enhancing biomedical implants to protecting national defense assets.

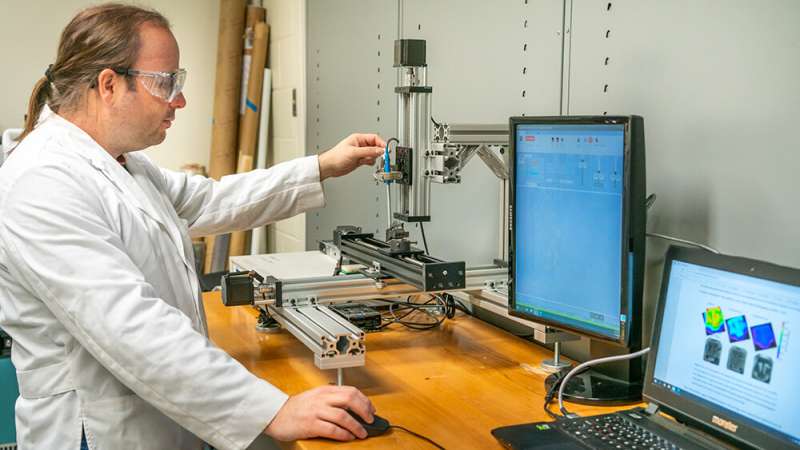

Texas A&M University researchers have developed a method of imprinting a hidden magnetic tag, encoded with authentication information, within manufactured hardware during the part fabrication process. The revolutionary process holds the potential to expose counterfeit goods more easily by replacing physical tags—such as barcodes or quick response (QR) codes—with these hidden magnetic tags, which serve as permanent and unique identifiers.

The project, titled "Embedded Information in Additively Manufactured Metals via Composition Gradients for Anti-Counterfeiting and Supply Chain Traceability," is a faculty partner project supported by the SecureAmerica Institute. It includes researchers from the Department of Materials Science and Engineering and the J. Mike Walker '66 Department of Mechanical Engineering at Texas A&M.

The team recently published its research in the journal Additive Manufacturing.

The faculty investigators on the project include Dr. Ibrahim Karaman, Chevron Professor I and department head of the materials science and engineering department; Dr. Raymundo Arroyave, professor of materials science and engineering and Segers Family Dean's Excellence Professor; and Dr. Richard Malak, associate professor of mechanical engineering and Gulf Oil/Thomas A. Dietz Career Development Professor. In addition to the faculty, Dr. Daniel Salas Mula, a researcher with the Texas A&M Engineering Experiment Station, and doctoral student Deniz Ebeperi—both members of Karaman's research group—have worked on the project. The team has also collaborated with Dr. Jitesh Panchal, professor of mechanical engineering at Purdue University.

Ensuring security and reliable authentication in manufacturing is a critical national concern, with the U.S. investing billions of dollars in manufacturing. Without such a method readily available, it can be nearly impossible to differentiate an authentic part or component from its counterfeit copy.

"The issue is that when I come up with an idea, device or part, it is very easy for others to copy and even fabricate it much more cheaply—though maybe at a lower quality," Karaman said. "Sometimes they even put the same brand name, so how do you make sure that item isn't yours? (The embedded magnetic tag) gives us an opportunity and a new tool to make sure that we can protect our defense and manufacturing industries."

Previous page

Previous page Back to top

Back to top