At present, microbial fuel cells

are mainly used in research laboratories to generate electricity. In order for

industrial applications to be considered in the future, the fuel cells must be

further developed so that they can produce consistently higher amounts of

electricity than is currently the case.

In a recent study published in the journal Biotechnology for Biofuels and Bioproducts, a research team from the University of Bayreuth has investigated factors playing a role in this. The choice of electrode material was shown to be particularly important for increasing stability and performance.

The electrical circuit in microbial fuel cells is kept running by the metabolism of microorganisms: These feed on organic compounds, releasing electrons that are transferred to the fuel cell's anode and from here to the cathode. The Bayreuth research team tested two different electrode materials in its investigations into optimizing microbial fuel cells: Carbon felt and modified stainless steel mesh.

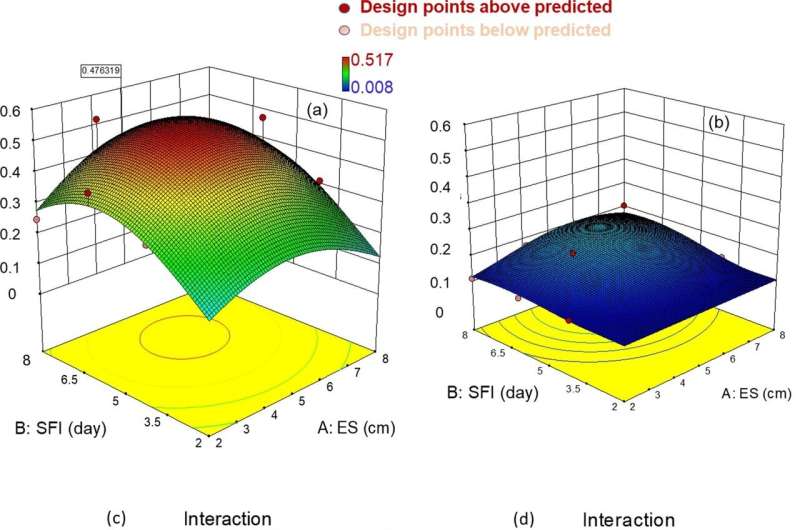

The best results were achieved when the electrodes of the cells were made of stainless-steel mesh, the surface of which was modified with highly conductive carbon black and environmentally friendly polymer binder. The optimal distance between the anode and cathode was about four centimeters. This reliably generated quantities of electricity that can be used in practice, for example, to power environmental monitoring sensors in remote regions—without being connected to the power grid.

Such fuel cells also make it possible to decontaminate petroleum hydrocarbon-contaminated soils while simultaneously producing electrical power. As the study shows, the efficiency of such detoxification strategies can be significantly increased if the suitable electrodes are available to capture the metabolic electrons.

"The significantly higher performance we were able to achieve with the microbial fuel cell using the newly developed electrodes can be explained by the fact that this material provides a larger specific surface area with which the microorganisms can interact and capacitive features to internally store the bioelectricity. Therefore, the number of electrons released from microbial metabolism that enter the circuit is particularly high here," says the study's first author, Meshack Imologie Simeon.

As a doctoral student in the University of Bayreuth's Bioprocess Engineering research group, he is researching possibilities for sustainable energy production based on bioelectricity. He first got in touch with scientists working on this topic in Bayreuth while he was a master's student at the University of Ibadan and a research assistant at the Federal University of Technology in Minna, Nigeria.

As the study shows, the stability of the fuel cells and the amount of electricity generated is also influenced by the time intervals at which the microorganisms are fed. Time-flexible feeding that kicks in when a weakening of the power generation became noticeable proved to be particularly effective. This was found to contribute more to an increase in fuel cell performance than regular feeding at equal time intervals.

The Bayreuth research team conducted its studies on a soil-based fuel cell (Soil Microbial Fuel Cells): This type of fuel cell works with bacteria and other microorganisms, such as those found in arable or forest soils. To identify the different types of microorganisms involved in power generation in the fuel cell, microbial DNA sequences were taken from the electrodes.

These sequences were analyzed for their origin under the direction of Dr. Alfons Weig in the Central Laboratory for DNA Analysis at the University of Bayreuth. Proteobacteria accounted for the largest proportion, but another bacterial strain—Firmicutes—was also frequently represented.

"Our studies show that natural soils contain a mixture of different bacterial strains that are capable of direct electron transfer and can be used in fuel cells to generate bioelectricity. As far as we have been able to determine, the ratio of these strains in the mixture has no significant influence on the stability and performance of the fuel cell. The greatest influence is exerted by the electrode materials, on which the ohmic resistance in the circuit and the electrical capacity of the fuel cells depend," emphasizes Prof. Dr. Ruth Freitag, Chair of Bioprocess Engineering at the University of Bayreuth.

Previous page

Previous page Back to top

Back to top