In a multi-year project,

researchers at Chalmers University of Technology in Sweden have developed

plasmonic plastic—a type of composite material with unique optical properties

that can be 3D-printed. This research has now resulted in 3D-printed optical hydrogen

sensors that could play an important role in the transition to green energy and

industry.

Interest in plasmonic metal nanoparticles and their many different applications has grown rapidly, developing across a broad spectrum over the past two decades. What makes these particles so special is their ability to interact strongly with light. This makes them useful for a wide range of applications: as optical components for medical sensors and treatments, in photocatalysis to control chemical processes, and in various types of gas sensors.

Plasmonic plastic

For six years, Chalmers researchers Christoph Langhammer, Christian Müller, Kasper Moth-Poulsen, Paul Erhart and Anders Hellman and their research teams collaborated in a research project on plasmonic plastic. At the time the project began, plasmonic metal nanoparticles were being used primarily on flat surfaces and required production in advanced cleanroom laboratories.

The researchers' starting point was to ask: what if we could produce large volumes of plasmonic metal nanoparticles in a sustainable way that would make it possible to manufacture three-dimensional plasmonic objects? This is where the plastic came into the picture. The properties of plastic materials mean that they can be shaped into almost any form, are cost-effective, have upscaling potential, and can be 3D-printed.

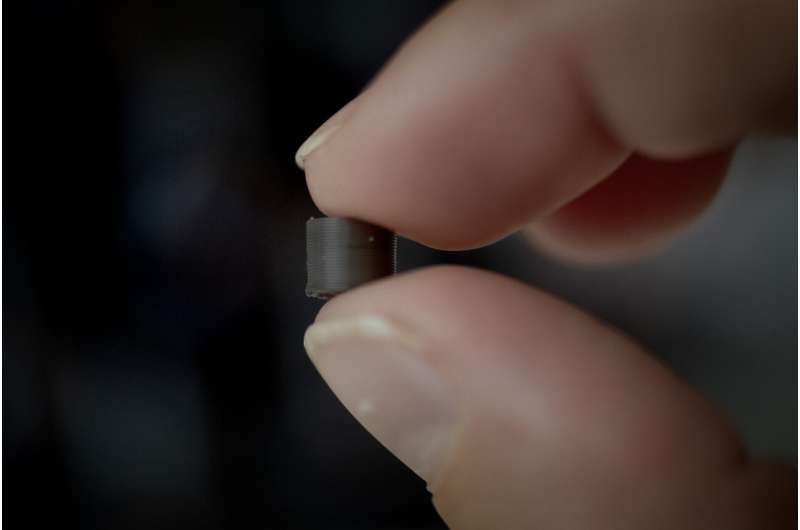

And it worked. The project resulted in the development of new materials consisting of a mix (or composite) of a polymer and colloidal, plasmonically active, metal nanoparticles. With these materials, you can 3D-print objects of anything from a fraction of a gram up to several kilograms in weight. Some of the most important research results from the entire project have now been summarized in an article in Accounts of Chemical Research.

3D-printed hydrogen sensors

Plasmonic sensors that can detect hydrogen are the target application for this type of plastic composite material that the researchers chose to focus on in their project. In doing so, they have pioneered an entirely new approach in the field of optical sensors based on plasmons, namely being able to 3D-print these sensors.

"Different types of sensors are needed to speed up development in medicine, or the use of hydrogen as an alternative carbon-free fuel. The interplay between the polymer and nanoparticles is the key factor when these sensors are fabricated from plasmonic plastic."

"In sensor applications, this type of plastic not only enables additive manufacturing (3D printing), as well as scalability in the material manufacturing process, but has the additional important function of filtering out all molecules except the smallest ones—in our application, these are the hydrogen molecules we want to detect. This prevents the sensor from deactivating over time," says Christoph Langhammer, professor at the Department of Physics, who led the project.

"The sensor is designed so that the metal nanoparticles change color when they come in contact with hydrogen, because they absorb the gas like a sponge. The color shift in turn alerts you immediately if the levels get too high, which is essential when you are dealing with hydrogen gas. At too high levels, it becomes flammable when mixed with air," says Christoph Langhammer.

Many applications possible

While a reduction in the use of plastics is desirable in general, there are numerous advanced engineering applications that are only possible thanks to the unique properties of plastics. Plasmonic plastics may now make it possible to exploit the versatile toolbox of polymer technology for designing novel gas sensors, or applications in health and wearable technologies as other examples. It may even inspire artists and fashion designers due to its appealing and tunable colors.

"We have shown that the production of the material can be scaled up, that it is based on environment-friendly and resource-efficient synthesis methods for creating the nanoparticles, and is easy to implement. Within the project, we chose to apply the plasmonic plastic to hydrogen sensors, but in reality only our imagination is the limit for what it can be used for," says Christoph Langhammer.

How plasmonic plastic works

Plasmonic plastic consists of a polymer, such as amorphous Teflon or PMMA (plexiglass), and colloidal nanoparticles of a metal that are homogenously distributed inside the polymer. At the nanoscale, the metal particles acquire useful properties such as the ability to interact strongly with light. The effect of this is called plasmons. The nanoparticles can then change color if there is a change in their surroundings, or if they change themselves, for example through a chemical reaction, or by absorbing hydrogen.

By dispersing the nanoparticles in the polymer, they are protected from the surroundings because larger molecules are not as capable of moving through the polymer as hydrogen molecules, which are extremely small. The polymer acts as molecular filter. This means that a plasmonic plastic hydrogen sensor can be used in more demanding environments, and will age less. The polymer also makes it possible to easily create three-dimensional objects of vastly different sizes that have these interesting plasmonic properties.

This unique interaction between the polymer, nanoparticles and light can be used to achieve customized effects, potentially in a wide range of products. Different types of polymers and metals contribute different properties to the composite material, which can be tailored to the particular application.

Previous page

Previous page Back to top

Back to top