One of the most used is PET (polyethylene terephthalate), which is found in many packaging and beverage bottles. Over time, this material wears down into smaller and smaller particles—so-called microplastics—which aggravates environmental problems. PET already accounts for more than 10% of global plastic production and recycling is scarce and inefficient.

Now, scientists from the Barcelona Supercomputing Center—Centro Nacional de Supercomputación (BSC-CNS), together with research groups from the Institute of Catalysis and Petrochemistry of the CSIC (ICP-CSIC) and the Complutense University of Madrid (UCM), have developed artificial proteins capable of degrading PET microplastics and nanoplastics and reducing them to their essential components, which would allow them to be broken down or recycled.

They have used a defense protein from the strawberry anemone (Actinia fragacea), to which they have added the new function after design using computational methods. The results are published in the journal Nature Catalysis.

Expanding nature

"What we are doing is something like adding arms to a person," explains Víctor Guallar, ICREA professor at the BSC and one of the authors of the work. These arms consist of just three amino acids that function as scissors capable of cutting small PET particles. In this case, they have been added to a protein from the anemone Actinia fragacea, which in principle lacks this function and which in nature "functions as a cellular drill, opening pores and acting as a defense mechanism," explains the researcher.

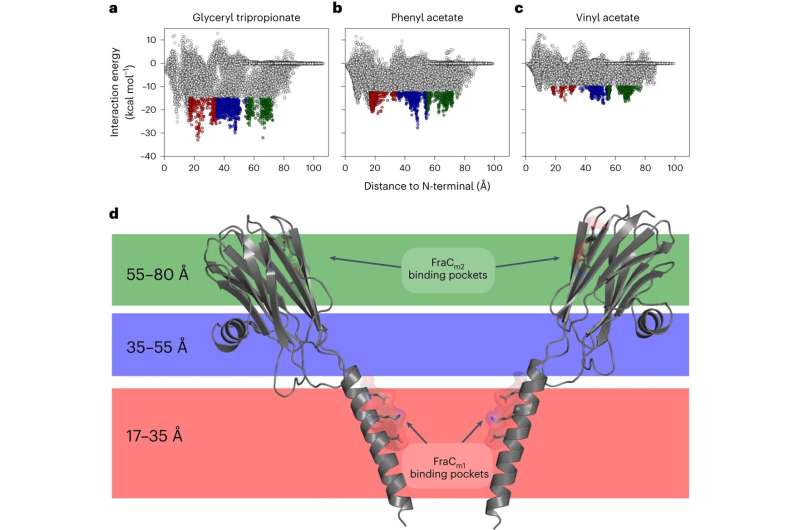

Machine learning and supercomputers such as the BSC's MareNostrum 4 used in this protein engineering allow "predicting where the particles are going to join and where we must place the new amino acids so that they can exert their action," says Guallar. The resulting geometry is quite similar to that of the PETase enzyme from the bacterium Idionella sakaiensis, which is capable of degrading this type of plastic and was discovered in 2016 in a packaging recycling plant in Japan.

The results indicate that the new protein is capable of degrading PET micro- and nanoplastics with "an efficiency between 5 and 10 times higher than that of PETases currently on the market and at room temperature," explains Guallar. Other approaches require temperatures above 70 °C to make the plastic more moldable, which leads to high CO2 emissions and limits its applicability.

In addition, the pore-like structure of the protein was chosen because it allows water to pass through and because it can be anchored to membranes similar to those used in desalination plants. This would facilitate its use in the form of filters, which "could be used in purification plants to degrade those particles that we do not see, but which are very difficult to eliminate and which we ingest," says Manuel Ferrer, Research Professor at the ICP-CSIC and also responsible for the study.

A design that allows purification and/or recycling

Another advantage of the new protein is that two variants were designed, depending on where the new amino acids are placed. The result is that each gives rise to different products.

"One variant breaks down the PET particles more thoroughly, so it could be used for degradation in sewage treatment plants. The other gives rise to the initial components needed for recycling. In this way we can purify or recycle, depending on the needs," explains Laura Fernández López, who is working on her doctoral thesis at the CSIC's Institute of Catalysis and Petrochemistry (ICP-CSIC).

The current design could already have applications, according to the researchers, but "the flexibility of the protein, like that of a multi-purpose tool, would allow new elements and combinations to be added and tested," explains Dr. Sara García Linares, from the Complutense University of Madrid, who has also participated in the research.

"What we are looking for is to combine the potential of proteins provided by nature and machine learning with supercomputers to produce new designs that allow us to achieve a healthy zero-plastics environment," says Ferrer.

"Computational methods and biotechnology can allow us to find solutions to many of the ecological problems that affect us," concludes Guallar.

Previous page

Previous page Back to top

Back to top