Researchers in

Researchers in

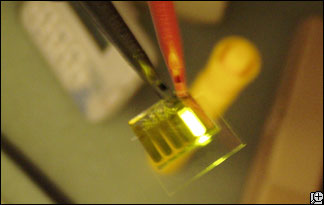

The technology, which blends traditional LEDs with newer light emitting electrochemical cells (LECs) could eventually be used to make cheap hi-definition televisions and other displays that are flat as film.

"Previous studies of LECs have always had problems with lifetime," said Yan Shao, scientist at the

"In our papers, we demonstrated for the first time that organic LECs can have a long lifetime; even longer time than organic LEDs."

Changing fewer bulbs is just the start.

LECs can be cheaply printed into large films instead of manufactured from parts, like LEDs. LEDs dim as they mature while LECs actually get brighter with age.

Eventually the hybrid light will dim, but at about a thousand times slower than a traditional LED.

The hybrid also uses less energy than an LED after about 15 minutes.

Previous LEC models took minutes to reach full illumination, which is not useful if you are in a dark room. They also died more quickly. By developing a hybrid light the researchers solved both of these problems.

LEDs use fast and very tiny electrons to create light. LECs create light by rearranging bulkier and slower atoms that have gained or lost an electron, known as ions.

When an electrical switch is flicked on the hybrid light, electrons flow immediately along metal barium and light up the material. After about 20 minutes though a transition occurs. Iron ions separate and start creating light instead of the barium electrons.

"Before the transition it is an LED," said Shao. "After the transition it is an LEC."

Since the hybrid still needs the metal barium it won not be as easy to manufacture as a pure LEC, but "it is not any harder to make than an LED," said Shao.

"They [LECs] will compete with traditional LEDs," said

Previous page

Previous page Back to top

Back to top