The crucial technological development happened recently at the Flexible Display Centre at Arizona State University. Using a novel lithographic process invented by HP Labs, the research arm of Hewlett-Packard, and an electronic ink produced by E Ink, a company spun out of the Massachusetts Institute of Technology, the centre’s researchers succeeded in printing flexible displays onto long rolls of a special plastic film made by DuPont. To make individual screens, the printed film is sliced up into sections rather as folios for magazines or newspapers would be cut from a printed web of paper.

The crucial technological development happened recently at the Flexible Display Centre at Arizona State University. Using a novel lithographic process invented by HP Labs, the research arm of Hewlett-Packard, and an electronic ink produced by E Ink, a company spun out of the Massachusetts Institute of Technology, the centre’s researchers succeeded in printing flexible displays onto long rolls of a special plastic film made by DuPont. To make individual screens, the printed film is sliced up into sections rather as folios for magazines or newspapers would be cut from a printed web of paper.

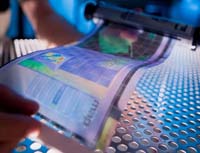

OVER the years, the screens on laptops, televisions, mobile phones and so on have got sharper, wider and thinner. They are about to get thinner still, but with a new twist. By using flexible components, these screens will also become bendy. Some could even be rolled up and slipped into your pocket like a piece of electronic paper. These thin sheets of plastic will be able to display words and images; a book, perhaps, or a newspaper or a magazine. And now it looks as if they might be mass produced in much the same way as the printed paper they are emulating.

The crucial technological development happened recently at the Flexible Display Centre at Arizona State University. Using a novel lithographic process invented by HP Labs, the research arm of Hewlett-Packard, and an electronic ink produced by E Ink, a company spun out of the Massachusetts Institute of Technology, the centre’s researchers succeeded in printing flexible displays onto long rolls of a special plastic film made by DuPont. To make individual screens, the printed film is sliced up into sections rather as folios for magazines or newspapers would be cut from a printed web of paper.

The resulting “electrophoretic” screens are lightweight and consume only a fraction of the power of a typical liquid-crystal display (LCD). Their first use is likely to be by the American army, which helped pay for the project. It hopes its soldiers will be able to use the screens as electronic maps and to receive information. The idea is that the flexible screens will replace some of the bulky devices that soldiers now have to lug around. If that works, the retail market beckons. The first trials of consumer versions could begin within a few years.

Flickering beginnings

Although printing flexible screens in this way will help to make them affordable, they still have a long way to go to catch LCDs. For that, two things need to happen. One is that the displays must turn from black-and-white to colour. The other is that they must be able to refresh their images at a rate fast enough to show moving pictures. Researchers at the Flexible Display Centre and elsewhere are working on ways to do that, and there seems little doubt it will happen. Yet even with their present limitations, flexible screens have some important advantages over LCDs.

For a start, LCDs are difficult and costly to make. Most are produced in huge, ultra-clean factories using batch processes similar to those for making silicon chips. Layers of material which work as filters, electrodes, transistors and the liquid crystal itself are deposited onto a thin glass plate to form a sandwich that is covered with another pane of glass. At each stage the layers are etched to make electrical connections. This is a fractious, finicky process and tiny defects in the materials, or failures in the alignment of the different layers, can result in 20% or more of a batch being scrapped. Moreover, the glass means LCDs are heavy and easily broken, as anyone who has dropped a laptop knows to his cost.

Another drawback is that LCDs consume a lot of power because they are lit from behind. An LCD works because, when an electrical field is applied to the transparent liquid crystals that form each picture element, or “pixel”, within the screen, the crystals become opaque. Red, green and blue filters then allow different colours to show within each pixel, but light has to be shone through them for this to happen. That, plus the fact that the liquid crystals will revert to transparency if the power goes off, mean an LCD eats batteries. It also means that the image can be hard to see in bright sunlight.

Electrophoretic displays work in a different way, using a form of electronic ink that has been under development since the 1970s. E Ink’s version employs tiny capsules filled with a clear fluid containing positively charged white particles and negatively charged black ones. The capsules are arranged as pixels and electric charges applied to each pixel pull either the black or the white particles towards the top of the capsule (and the opposite colour to the bottom). Unlike an LCD’s, this image does not require backlighting. Instead, the user relies on reflected light, as he would if he were reading a sheet of printed paper. Moreover, once the particles in the capsules have settled down they stay put. That means the image remains on the screen without drawing power. A further dose of electricity is required only when the image changes; when a user “turns” to the next page, for example. Not only does this mean that electrophoretic displays are cheaper to run, the lack of constant refreshment makes them more comfortable to read—as comfortable, it is claimed, as printed paper.

Kindling the fire

In fact, electrophoretic displays are already available, but they are built on glass in a similar way to an LCD. One such device is the Kindle, launched by Amazon, an American online retailer, in November 2007. Thanks in part to a ringing endorsement by Oprah Winfrey on her television show, it is now a big hit and prospective purchasers face long delays getting their hands on one. The Kindle, which costs $359, is about the size of a slim paperback (see picture below). It can download books and other publications directly using a built-in wireless connection, and offers electronic editions of some newspapers.

It is not alone, though. Its rivals include Sony’s Reader, and a device with a larger screen launched late last year by iRex, a Dutch company. And, later this year, an electrophoretic reader that is built the LCD way, but on plastic, rather than on glass, will also be launched to take them on.

Plastic Logic, the firm that makes this reader, was founded by researchers at the University of Cambridge, has its headquarters in Silicon Valley and does its manufacturing in Germany. The firm uses an adapted version of LCD manufacturing which employs electronic ink and plastic substrates to make its screens. Plastic Logic’s prototype reader, which has a screen about the size of a magazine, is a mere 7mm thick and weighs less than 450 grams. It should run for a week in normal use before its battery needs recharging.

All the news that’s fit not to print

All the news that’s fit not to printPlastic Logic says its reader will be aimed at businessmen who might want to store, on a single machine capable of being slipped into their briefcase, all the paper documents and spreadsheets that at present they normally print out. Books and periodicals can be read too. And for those who think they would miss the ability to scribble comments and underline things that paper provides, the reader’s screen will be touch-sensitive, allowing such annotations to be made.

Even Plastic Logic’s approach, though, is likely to be transitional. If Hewlett-Packard’s “self-aligned imprint lithography”, as it describes its new technology, can be commercialised, it will take the manufacture of screens through what has proved a crucial transition in every industry in which it has happened—from batch processing to continuous manufacture.

The breakthrough here was to work out a way to simplify the process by which the electronic circuit that controls the pixels is carved out of layers of conducting, semiconducting and insulating materials. In standard silicon-based electronics, this involves the repeated application of resistive materials to protect those parts of the layer being etched that need to be preserved. Hewlett-Packard’s scientists, however, have worked out how to print a layer of resistive material of variable height on top of all the other layers. After each stage of the etching process a fixed depth of this is dissolved away, exposing a different part of the circuit to the etching chemicals.

The result is a continuous process, much like a printing press. This promises to become a cost-effective mass-production method which Hewlett-Packard will license to other producers, says Prith Banerjee, the company’s research director. Once that happens, he hopes, flexible screens could be used in all sorts of devices.

Colour section

The one feature these screens do not yet offer is colour and, though colour versions will surely come to market, no one is yet sure which version will succeed. Electrophoretic displays can use coloured particles and filters to produce red, green and blue subpixels, but as each colour occupies only one third of a pixel’s area, the brightness of the image is correspondingly reduced. Liquavista, a spin-off from Philips, a big Dutch electronics company, is trying something called “electrowetting”. This uses an electrical field to modify the surface tension of coloured oils and water within pixels that are mounted on a flexible Teflon base. As each pixel is activated, the wetting properties of the oil and water change, making colours visible.

Another approach is to use materials that emit light. Some firms, such as Sony, are looking at organic light-emitting diodes composed of thin films of organic molecules which generate light in response to an electric current. This approach is reckoned to have potential for use in ultra-thin, wall-mounted television sets.

Photonic crystals are a further alternative. These are tiny particles that have a crystal structure which influences the flow of photons, the particles of light. By changing the structure of such a crystal slightly, using an electric charge, the colour of the light reflected by that crystal will change too. Tune the crystals appropriately and you can create different colours.

There are also hybrid methods, like that used by Adrian Geisow at HP Labs’ campus in Bristol, England. He has taken a conventional approach to generating colour, using liquid crystals and red, green and blue filters. However, he has done so in a plastic film produced in a printing-type process. The screen can be backlit, like a standard LCD, but it is capable of retaining its image because the material the liquid crystals sit on encourages the pixels to stay transparent or opaque once they have been switched. However it is eventually done, Dr Geisow is convinced that putting colour into flexible screens is what will turn them into a very big picture indeed.

Previous page

Previous page Back to top

Back to top