Advanced plasma-based etching is a key enabler of Moore's Law that observes that the number of transistors on integrated circuits doubles nearly every two years. It is the plasma's ability to reproduce fine patterns on silicon that makes this scaling possible and has made plasma sources ubiquitous in microchip manufacturing.

A groundbreaking fabrication technique, based on what is called a DC-augmented capacitively coupled plasma source, affords chip makers unprecedented control of the plasma. This process enables DC-electrode borne electron beams to reach and harden the surface of the mask that is used for printing the microchip circuits. More importantly, the presence of the beam creates a population of suprathermal electrons in the plasma, producing the plasma chemistry that is necessary to protect the mask. The energy of these electrons is greater than simple thermal heating could produce -- hence the name "suprathermal." But how the beam electrons transform themselves into this suprathermal population has been a puzzle.

A groundbreaking fabrication technique, based on what is called a DC-augmented capacitively coupled plasma source, affords chip makers unprecedented control of the plasma. This process enables DC-electrode borne electron beams to reach and harden the surface of the mask that is used for printing the microchip circuits. More importantly, the presence of the beam creates a population of suprathermal electrons in the plasma, producing the plasma chemistry that is necessary to protect the mask. The energy of these electrons is greater than simple thermal heating could produce -- hence the name "suprathermal." But how the beam electrons transform themselves into this suprathermal population has been a puzzle.

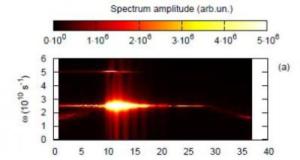

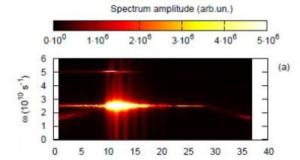

Now a computer simulation developed at the U.S. Department of Energy's Princeton

Plasma Physics Laboratory in collaboration with the University of Alberta has shed light on this transformation. The simulation reveals that the initial DC-electrode borne beam generates intense plasma waves that move through the plasma like ripples in water. And it is this beam-plasma instability that leads to the generation of the crucial suprathermal electrons.

Understanding the role these instabilities play provides a first step toward still-greater control of the plasma-surface interactions, and toward further increasing the number of transistors on integrated circuits. Insights from both numerical simulations and experiments related to beam-plasma instabilities thus portend the development of new plasma sources and the increasingly advanced chips that they fabricate.

Previous page

Previous page Back to top

Back to top