Concrete is one of the world’s

most commonly used materials, and unfortunately its production is a major

source of carbon dioxide in the atmosphere. Now, engineers at Purdue University

have developed a new cement recipe that can absorb CO2 twice as fast as usual,

hopefully turning it into a useful carbon sink.

Concrete production accounts for over eight percent of the world’s carbon dioxide emissions, and with demand increasing every year researchers have been investigating ways to make concrete more environmentally friendly. Some steps have included changing the recipe to reduce or replace the binding agent that produces the chemical reaction that emits CO2. Some alternatives even involve capturing CO2 from other sources and using that in the mix.

But another avenue of research gives the material a more active role. Once it’s laid, concrete naturally absorbs CO2 from the atmosphere over its lifetime. It’s not enough to fully counter the emissions released during its production, but it at least helps reduce the footprint. Some studies have found ways to boost that absorption to make concrete even greener – and now, the Purdue team has discovered a new way to do so.

“We can’t wait decades for concrete to absorb the carbon dioxide produced in its manufacturing process,” says Mirian Velay-Lizancos, lead author of the study. “My team is making the concrete itself absorb carbon dioxide faster and in greater volumes. We’re not trying to change the way we use concrete; we’re making the concrete work for us.”

The secret ingredient is titanium dioxide. By mixing small portions of this material in with the cement paste, the team found that it reduced the size of calcium hydroxide molecules, which made the concrete more efficient at absorbing carbon dioxide.

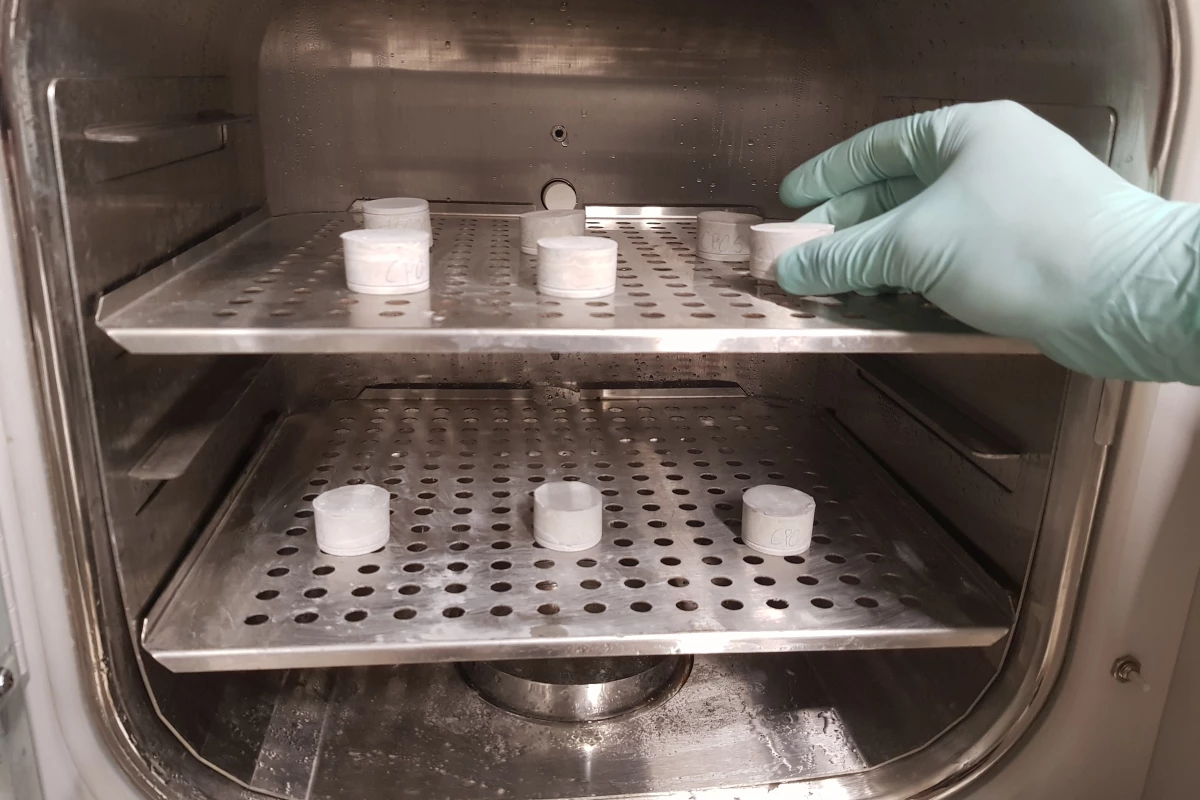

The team tested the absorption of the concrete by placing samples in a chamber filled with high concentrations of CO2 for 24 hours, then analyzed their mass changes over time and performed 3D X-ray scans of the pore structure. They found that titanium dioxide could almost double the speed at which concrete absorbed CO2.

That said, it wasn’t just a matter of throwing in more titanium dioxide and boosting the effect even further. The team found that it worked up until a certain percentage, before dropping again. That percentage depended upon the water-to-cement ratio and the age of the cement.

The researchers plan to investigate the new cement recipe further, in hopes of making it more sustainable and durable.

The research was published in the journal Construction and Building Materials.

Previous page

Previous page Back to top

Back to top