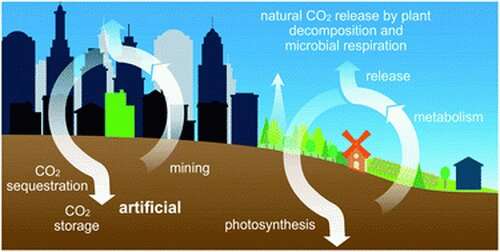

Plants are unparalleled in their

ability to capture CO2 from the air, but this benefit is temporary, as

leftover crops release carbon back into the atmosphere, mostly through

decomposition. Researchers have proposed a more permanent, and even useful,

fate for this captured carbon by turning plants into a valuable industrial

material called silicon carbide (SiC)—offering a strategy to turn an

atmospheric greenhouse gas into an economically and industrially valuable

material.

In a new study, published in the journal RSC Advances on April 27, 2021, scientists at the Salk Institute transformed tobacco and corn husks into SiC and quantified the process with more detail than ever before. These findings are crucial to helping researchers, such as members of Salk's Harnessing Plants Initiative, evaluate and quantify carbon-sequestration strategies to potentially mitigate climate change as CO2 levels continue to rise to unprecedented levels.

"The study offers a very careful accounting for how you make this valuable substance and how many atoms of carbon you've pulled out of the atmosphere. And with that number, you can start to extrapolate what role plants could play in mitigating greenhouse gases while also converting an industrial byproduct, CO2, into valuable materials by using natural systems like photosynthesis," says co-corresponding author and Salk Professor Joseph Noel.

SiC, also known as carborundum, is an ultrahard material used in ceramics, sandpaper, semiconductors and LEDs. The Salk team used a previously reported method to transform plant material into SiC in three stages by counting carbons at each step: First, the researchers grew tobacco, chosen for its short growing season, from seed. They then froze and ground the harvested plants into a powder and treated it with several chemicals including a silicon-containing compound. In the third and final stage, the powdered plants were petrified (turned into a stony substance) to make SiC, a process that involves heating the material up to 1600 C.

"The rewarding part was that we were able to demonstrate how much carbon can be sequestered from agricultural waste products like corn husks while producing a valuable, green material typically produced from fossil fuels," says first author Suzanne Thomas, a Salk staff researcher.

Through elemental analysis of the plant powders, the authors measured a 50,000-fold increase in sequestered carbon from seed to lab-grown plant, demonstrating plants' efficiency at pulling down atmospheric carbon. Upon heating to high temperatures for petrification, the plant material loses some carbon as a variety of decomposition products but ultimately retains about 14 percent of the plant-captured carbon.

The researchers calculated that the process to make 1.8 g of SiC required about 177 kW/h of energy, with the majority of that energy (70 percent) being used for the furnace in the petrification step. The authors note that current manufacturing processes for SiC carry comparable energy costs. So while the production energy required means that the plant-to-SiC process isn't carbon neutral, the team suggests that new technologies created by renewable energy companies could bring down energy costs.

"This is a step towards making SiC in an environmentally responsible approach," says co-corresponding author and Salk visiting scientist James La Clair.

Next, the team hopes to explore this process with a wider variety of plants, in particular plants like horsetail or bamboo, that naturally contain large amounts of silicon.

Previous page

Previous page Back to top

Back to top