Graphene

nanoribbons (GNRs) are narrow and long strips of graphene with widths below 100

nm. GNRs that have smooth edges, a sizable bandgap and high charge carrier

mobility could be highly valuable for a wide range of electronic and

optoelectronic applications. So far, however, engineers have not yet introduced

a method to prepare these useful components on a large scale.

Researchers at Shanghai Jiao Tong University, Stanford University, and other institutes in the US and China, have recently devised a new strategy to create GNRs with smooth edges that are below 10 nm in width. This method, introduced in a paper published in Nature Electronics, is based on the use of squashed carbon nanotubes (CNTs), tubes made of carbon that typically have diameters in the nanometer scale.

"The idea behind our work is that if carbon nanotubes (CNTs) can be squashed into GNRs, we would be capable of producing narrow (sub-5-nm wide) GNRs from CNTs that have small diameters," Prof. Changxin Chen and Wendy L. Mao, two of the researchers who carried out the study, told Phys.org. "Moreover, the GNRs prepared using this method will be much narrower than those obtained by previous methods."

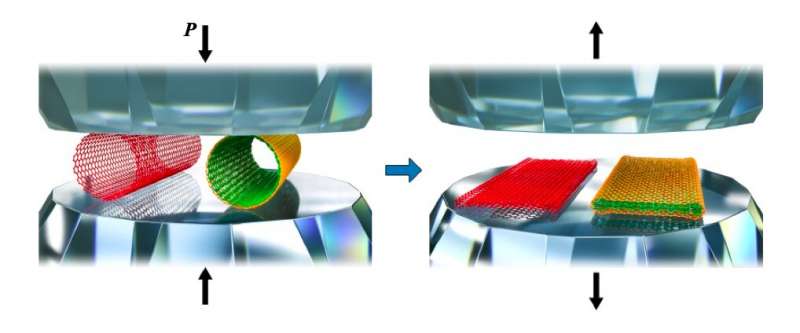

The recent study by Prof. Chen, Mao, Prof. Hongjie Dai and their colleagues was a joint effort between their respective research groups at Shanghai Jiao Tong University and Stanford University, with additional input from other institutions. A team led by Prof. Chen and Dai mainly developed the method and processes of the high-pressure/thermal treatment to squash the CNTs into GNRs, as well as on gathering characterizations of the prepared GNRs, calculations and device performance measurements. Prof. Wendy Mao's research group conducted the high-pressure diamond anvil cell (DAC) experiments through which the CNTs were squashed.

Another objective of this recent collaboration was to achieve atomically smooth edges throughout the whole GNRs, by forming edge-closed GNRs that exhibited high material and device mobility. To produce their sub-10-nm-wide and long GNRs with atomically smooth closed edges, the researchers squashed CNTs together using the high-pressure and thermal treatment method devised by Chen and his team.

"We used a DAC for the high-pressure treatment of CNTs," Chen and Mao explained. "The CNT samples were sealed in a sample chamber in the DAC and then were compressed between the tips of two diamond anvils. To stabilize the squashed sample structure, we conducted a thermal treatment on the sample while it was at high pressure."

The GNRs created by Chen, Mao, Dai and their colleagues have atomically smooth, closed edges and very few defects. Using the method they devised, the team was even able to produce sub-5-nm GNRs with a minimum width of 1.4 nm. Remarkably, they found that a field effect transistor (FET) based on a 2.8-nm-wide edge-closed GNR exhibited a high Ion/Ioff ratio of >104, field-effect mobility of 2,443 cm2 V−1 s−1 and on-state channel conductivity of 7.42 mS.

"Our research proves that sub-10-nm-wide semiconducting graphene nanoribbons with atomically smooth closed edges can be produced by squashing carbon nanotubes using a combined high-pressure and thermal treatment," Chen and Mao said. "With this approach, nanoribbons as narrow as 1.4 nm can be created. The edge-opened nanoribbons were also fabricated using nitric acid as the oxidant to selectively etch the edges of the squashed nanotubes under high pressure."

The study could have important implications for the development of new electronic and optoelectronic devices. In the future, the method devised by Chen, Mao, Dai and their colleagues could be used to produce high-quality, narrow, and long semiconducting GNRs.

In addition, their fabrication strategy allows engineers to control a GNR's edge types. This could help to explore the fundamental properties and practical applications of GNRs in electronics and optoelectronics further. Ultimately, the method developed by Chen, Mao, Dai and their colleagues could also be adapted to also synthesize other desirable materials-based nanoribbons using squashed nanotubes or to flatten other fullerene materials.

"Now that we have demonstrated the potential of our approach, we are investigating ways to make the synthesis conditions more practical and ways to scale up the synthesis of GNRs (e.g., decreasing the pressure needed for squashing CNTs by regulating the temperature of the sample in the high-pressure treatment or introducing additional deviatoric-stress component in the pressure)," Chen and Mao added. "In our next studies, we also plan to explore more unique characteristics of the edge-closed GNRs we created."

Previous page

Previous page Back to top

Back to top