Ammonia

is one of many pollutants present in wastewater and can be toxic for marine and

terrestrial life. Therefore, in a process called air stripping, it is removed

from wastewater and later used as a fertilizer or fuel. Air stripping converts

ammonia into a gas that can then escape the wastewater from its surface. But

this process is not efficient: It is energy-intensive, and requires specific

temperatures, air supply, and many chemicals, making it expensive.

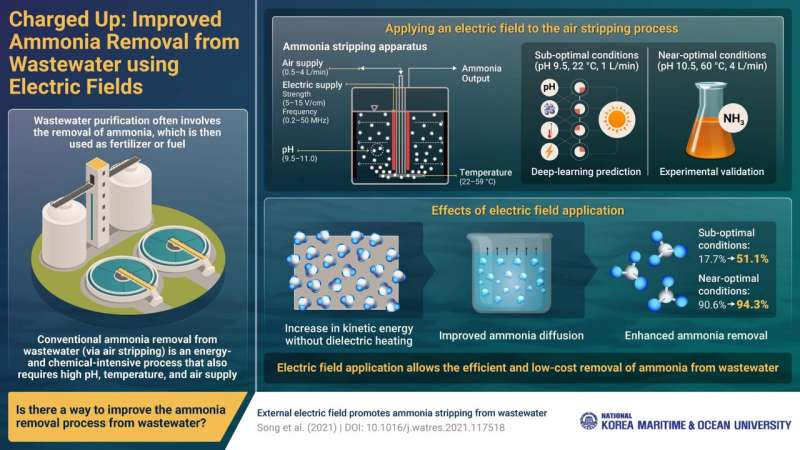

Addressing these drawbacks, in a study published in Water Research, researchers from South Korea have demonstrated that the simple application of an electric field during air stripping can substantially improve the efficiency of ammonia removal, even under sub-optimal conditions. "So far, the removal of ammonia from wastewater was thought to be dependent on only pH, temperature, and air supply. However, we have shown that an electrical field can also act as a modulator of this process," says Prof. Young-Chae Song, the lead investigator on this study.

Prof. Song and his team used a combination of live experiments with an ammonia stripping tank and deep learning to understand how electric fields of different strengths influence the efficiency of ammonia removal from wastewater. They found that electric fields with an alternating current of 50 MHz and a power of 15 V/cm significantly improves the ammonia removal efficiency, increasing it from 51% to 94%, even under sub-optimal conditions. Therefore, improved ammonia yields could be achieved while considerably reducing the consumption of energy and chemicals.

Prof. Song comments, "Our simulations showed that electric field application provides a similar efficiency of ammonia removal to conventional methods at a much lower temperature, air supply, and pH. Moreover, the energy needed to power the electric field is a minute fraction of the energy required to achieve these 'optimal' conditions."

Indeed, this new electric field-coupled platform could provide a more economical way of stripping ammonia from wastewater and reducing the carbon footprint associated with this process.

Previous page

Previous page Back to top

Back to top