A research team has developed an

inorganic-organic thermoelectric composite that promises competitive pricing

while addressing efficiency and flexibility challenges in thermoelectric

technology.

Thermoelectric technology, an energy conversion technology between heat and electricity, represents an eco-friendly approach to converting waste heat into electricity. It is known for its ability to generate power from heat and provide cooling effects using electricity.

With applications ranging from waste heat recovery generation and refrigerant-free cooling devices in traditional industries to precision temperature control systems through localized cooling and heating and continuous power supply energy harvesters in advanced new industries, its versatility is receiving significant attention.

Despite ongoing research and development on various types of bulk and thin-film thermoelectric materials and devices, owing to the advantages of thermoelectric technology, the chronic issue of lower efficiency and flexibility, as compared to other energy conversion technologies, has been a persistent challenge.

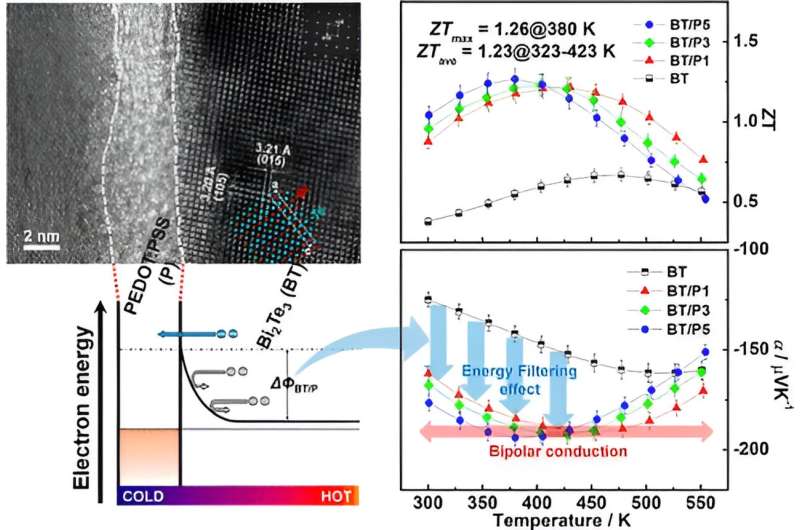

Accordingly, the team at the Nano Convergence Research Department, led by Principal Researcher Kim Cham, manufactured an inorganic-organic thermoelectric composite by combining conventional inorganic thermoelectric materials with conductive polymers to maximize the efficiency and flexibility of thermoelectric materials.

Notably, the team developed a manufacturing process capable of synthesizing and mixing organic and inorganic components, overcoming the technical challenge of maintaining a uniform phase and securing high density. The inorganic-organic thermoelectric composite produced through this process boasts not only excellent thermoelectric properties but also flexibility and cost reduction.

Principal Researcher Kim Cham of DGIST's Nano Convergence Research Department stated, "Through this research, we were able to develop a new material that maximizes the utility of eco-friendly energy technology, i.e., thermoelectric technology. We will continue our efforts to scale up the production technology of thermoelectric composites and stabilize their performance for commercialization, aiming for wide application in both traditional and cutting-edge new industries."

The paper is published in the journal ACS Applied Materials & Interfaces.

Previous page

Previous page Back to top

Back to top