Clingy barnacles might be something of a nuisance for seafarers, but these stubborn shellfish and their relatives could hold the key to a new breed of sticky materials. Engineers from MIT have created waterproof adhesives based on the proteins that give these creatures such qualities, a development that could one day be used in ship repairs or medical applications.

"A lot of underwater organisms need to be able to stick to things, so they make all sorts of different types of adhesives that you might be able to borrow from," says Timothy Lu, associate professor of biological engineering, electrical engineering and computer science and senior author of the research paper.

With regards to mussels, these adhesives are known as mussel foot proteins. Scientists have mimicked these proteins before through the engineering of E. coli bacteria, though Lu says this hasn't represented the true complexities of the natural adhesive.

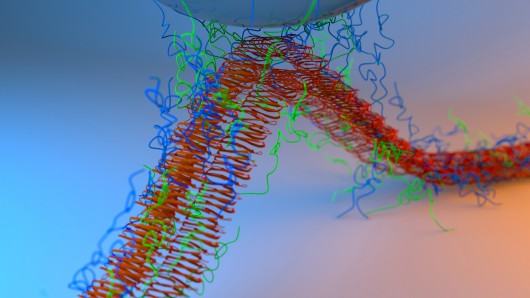

In the new study, the MIT researchers engineered bacteria to create two types of foot proteins and mix them with curli fibers – bacterial proteins with the ability to gather together and create large meshes. The team then purified the proteins from the bacteria and incubated them, resulting in a dense mesh and a material capable of binding to both dry and wet surfaces.

Putting the new material to the test, the team found that it clung to instruments made from silica, gold and polystyrene. It's claimed that the hybrid material is stronger than the natural mussel adhesives and the strongest of any such engineered material to date. It was also observed that the adhesive was at its most effective when made from equal parts of the two foot proteins, rather than an uneven ratio.

One limitation is that the researchers were only able to produce small amounts of the material at a time. They are now working to overcome this, and experimenting with different types of mussel foot proteins as a means of improving its adhesive strength. Their vision even involves plans to create a "living glue", a film of bacteria that detects damage and automatically produces the adhesive to repair it.

Previous page

Previous page Back to top

Back to top