Various software packages can be

used to evaluate products and predict failure; however, these packages are

extremely computationally intensive and take a significant amount of time to

produce a solution. Quicker solutions mean less accurate results.

To combat this issue, a team of Penn State researchers studied the use of machine learning and image colorization algorithms to ease computational load, maintain accuracy, reduce time and predict strain fields for porous materials. They published their work in the Journal of Computational Materials Science with accompanying presentations and proceedings in Procedia Engineering.

"There is always a human side to design," said Chris McComb, assistant professor of engineering design in the School of Engineering Design, Technology, and Professional Programs. "There are potentially life-saving products that require additive manufacturing and can be frustrating to design. These simulations and evaluations take a long time, so it's important for us to help make it faster and easier to deliver safe products."

The authors include Pranav Milind Khanolkar, a spring 2020 industrial engineering master's alumnus; Aaron Abraham, industrial engineering undergraduate student; Saurabh Basu, assistant professor of industrial engineering; and McComb.

As part of his master's degree, Khanolkar investigated the use of ABAQUS, a widely used software for performing detailed simulations in additive manufacturing. According to the researchers, the software can be problematic because its speed and performance level rely on a computer's hardware processing power.

To speed up the simulations, the team implemented machine learning algorithms to reduce the exclusive use of computationally demanding finite element analysis (FEA). Explained by ABAQUS, FEA can predict crack, impact and crash events with material failure, as well as the dynamics, controls and joint behavior of a product.

Machine learning algorithms can be used to predict mechanical properties and material parameters, which is swift and uses less computational power than traditional FEA.

Khanolkar and Abraham used ABAQUS to perform high-quality FEA over hundreds of hours of work and thousands of data samples on simulated, structurally flawed mechanical parts. They then used these data samples to train machine learning algorithms to estimate the FEA results and maintain high accuracy in only a fraction of the time.

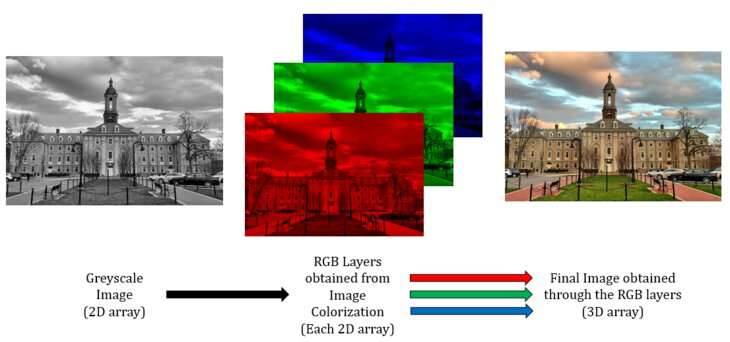

The team applied image colorization algorithms to material microstructure data, and repurposed algorithms that are typically used to add color to black-and-white photos.

In the original case, the algorithms take a black-and-white photo and return the red, green and blue channels for a new, colored version. In the team's work, the algorithm takes a simple image of the material microstructure and returns channels representing different types of potential failures in the product.

"Volumetric defects can affect the performance of a component in several ways, so it's key to understand this effect during the design process of a component," Basu said. "When defects may be unavoidable, like in additively manufactured components, this understanding can help decide how a design may be altered to make the presence of defects tolerable. This can be done by running different design scenarios and ultimately altering the design to achieve a more structurally responsible part. The insights resulting from our study are a first step toward such a framework."

For Khanolkar, the work helped him deeply understand machine learning techniques, providing direction for his current doctoral studies in mechanical and industrial engineering at the University of Toronto.

"Using intelligent technology to help people and empower their creativity and empathy during the design process is important," Khanolkar said. "These algorithms need lots of computational power and using artificial intelligence in this paper allows designers to be more creative without impacting production cost."

Previous page

Previous page Back to top

Back to top