Monolayer-thick sheets of hexagonal boron nitride, or "white graphene," share many of the properties of graphene, including exceptional mechanical strength and thermal conductivity. But one important point of difference is its electrical conductivity, with graphene being a conductor, while white graphene is an insulator. Now researchers have developed a process to create a virtually perfect monolayer of white graphene, making a dream team pairing of graphene and white graphene substrate for use in next generation electronic devices a possibility.

Monolayer-thick sheets of hexagonal boron nitride, or "white graphene," share many of the properties of graphene, including exceptional mechanical strength and thermal conductivity. But one important point of difference is its electrical conductivity, with graphene being a conductor, while white graphene is an insulator. Now researchers have developed a process to create a virtually perfect monolayer of white graphene, making a dream team pairing of graphene and white graphene substrate for use in next generation electronic devices a possibility.

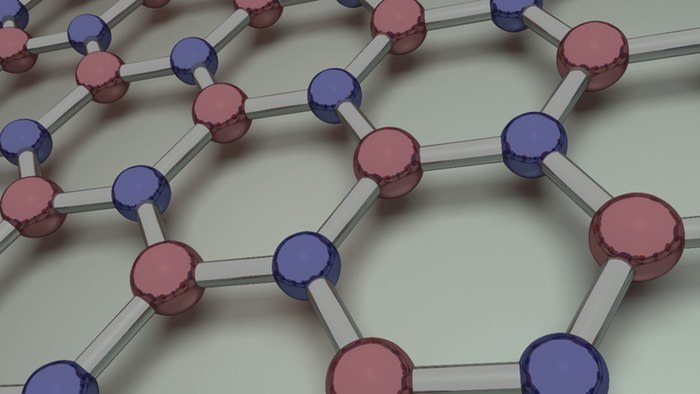

Researchers at the Department of Energy's Oak Ridge National Laboratory (ORNL) have been working with hexagonal boron nitride (where alternate boron and nitrogen atoms are linked to form interlocking hexagonal rings), which is a substance known for its exceptionally low coefficient of friction and more regularly used in such things as lubricants and cosmetics. The new ORNL formula, however, takes the standard substance and subtly adjusts the method of chemical deposition used in its creation to create white graphene that is particularly smooth at an atomic level.

"Various hexagonal boron nitride single crystal morphology – triangle to hexagon – formulations have been mentioned in theoretical studies, but for the first time we have demonstrated and explained the process," says postdoctoral associate Yijing Stehle, of ORNL "[We created] a more gentle, controllable way to release the reactant into the furnace and [figured] out how to take advantage of inner furnace conditions. These two factors are almost always neglected."

With far greater transparency, white graphene is also chemically inert, and features the high mechanical strength, high melting point, and thermal conductivity properties of graphene. The most important point of difference, however, is that white graphene is an insulator of electricity, which means that it would make the perfect accompanying material to pair with graphene to form a substrate that is not only extremely thin, but transparent. The researchers see the possibilities in this as the foundation for a new era of ultra-thin electronics in phones, laptops, tablets and a raft of other devices.

"Imagine batteries, capacitors, solar cells, video screens and fuel cells as thin as a piece of paper," said Stehle. In this vein, Stehle and her colleagues are currently working on creating a graphene hexagonal boron 2-D capacitor and a fuel cell prototype that are both super thin and transparent.

Already other researchers are taking advantage of the slightly dissimilar properties of these two ultrathin materials to manipulate light or even soak up oil spills. With this latest recipe, ORNL scientists are hopeful of helping to unlock the full potential of graphene, which is yet to realize performance consistent with its theoretical value. The researchers believe white graphene could be the key to this as graphene on a white graphene substrate displays electron mobility several thousands of times greater than graphene deposited on other substrates.

This property alone could increase data transfer rates at orders of magnitude greater than those possible now. "Imagine your message being sent thousands of times faster," said Stehle.

Importantly, the white graphene is produced in a standard atmospheric pressure chemical vapor deposition process, which Stehle and her colleagues believe could easily be scaled up to commercial production volume levels at a reasonable cost.

Previous page

Previous page Back to top

Back to top